Nippon Mecha Chemical Co. Ltd.

Jan 30, 2025

What is the difference between rust removers and discoloration removers for copper?

Currently, our company does not offer removal agents that strictly differentiate between “rust” and “discoloration.” This is because the term “discoloration” is used broadly, making it difficult to develop an optimal chemical agent for each case.

In general, “rust” refers to substances formed when metals oxidize. On the other hand, “discoloration” describes a state where the surface undergoes various physical or chemical changes and appears different in color compared to a reference standard.

If the cause of attachment, such as oxygen in the case of rust, can be clearly identified, it is easier to select an appropriate removal agent. However, when the type of attached substance or the manner of attachment varies or involves multiple factors, it becomes necessary to carefully determine the most suitable chemical agent on a case-by-case basis.

Our product lineup includes rust removers specifically for copper, such as KC-12A and MECHARINSE Cu-980.

- KC-12A is designed to remove rust while minimizing the impact on the base material.

- MECHARINSE Cu-980, on the other hand, works by slightly dissolving the surface to reveal a fresh layer underneath.

As a result, Cu-980 removes rust and discoloration more quickly but has a stronger impact on the base material.

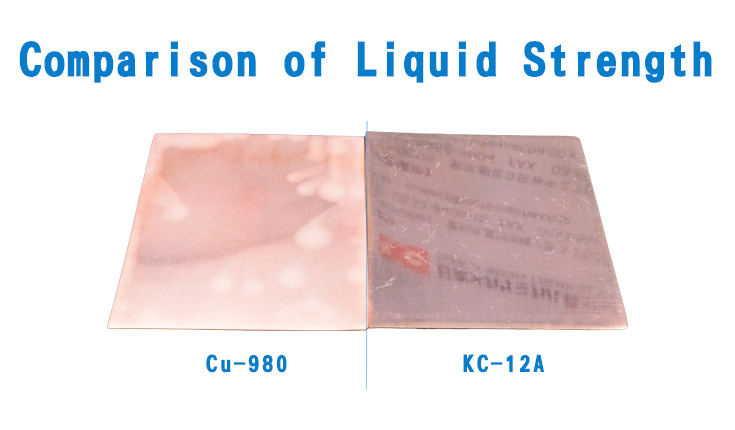

The image above shows the results after immersing the samples in KC-12A and MECHARINSE Cu-980 for the same duration (about 1 minute).

- The metal surface treated with KC-12A reflects light, indicating minimal impact on the base material.

(The images were taken in a way that reflects text on both treated surfaces for comparison.)

Rust and discoloration can vary in depth and severity.

To determine the most suitable product, as well as whether to use it diluted or in its original concentration, we recommend conducting sample tests while evaluating the results.

In addition to copper rust removers, we also offer anti-rust agents, additives to prevent discoloration, and processing oils specifically for copper.

Please feel free to contact us for further details.