Nippon Mecha Chemical Co. Ltd.

Sep 06, 2024

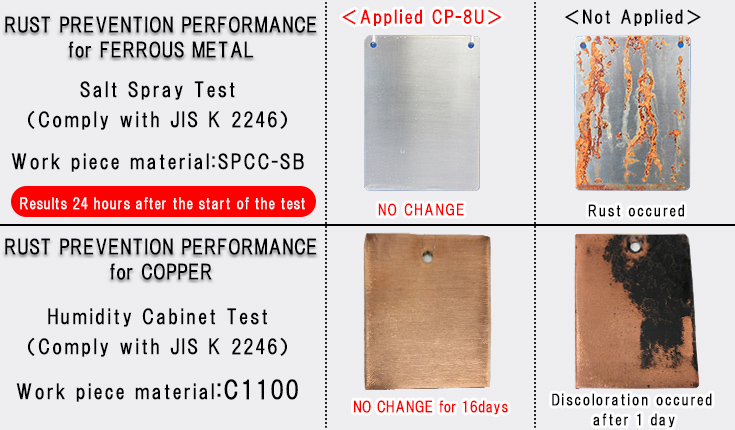

CP-8U

“Can’t CP-6 be used to prevent copper from rusting?”

CP-8U was developed in response to this customer’s request.

When we asked for more details,

“We have been using CP-6 to prevent rusting of iron-based parts and are very satisfied with it.”

“We want to store another processed product for 2-3 months after assembling iron and copper parts.”

CP-6 is a general-purpose type for iron materials. We also have CP-CU as a rust inhibitor specifically for copper.

We create products (considering the optimal compounding ingredients) that bring out the maximum performance according to the required application.

For example, CP-6 uses protective ingredients that are extremely effective against iron, but you cannot expect them to be effective against copper.

On the other hand, CP-CU effectively suppresses discoloration of copper, but you cannot expect them to be effective against iron.

Therefore, if you use one of the rust inhibitors on a product that combines iron and copper, you cannot expect the rust prevention effect on the incompatible material.

However, applying separate liquids to each part (iron and copper) is a very troublesome process.

To solve these issues, we discovered a formula that works effectively on both iron and copper materials, and completed CP-8U.

CP-8U can be used to store iron and copper bimetals and built-in parts.

We also received feedback from customers who use both CP-6 and CP-CU saying, “With just one, there’s no need to worry about using the wrong rust-preventive oil.”

According to the developers, the base formula ideas were narrowed down to a few patterns based on our company’s technology and know-how to date, and they smoothly arrived at the finished product.

Our researchers may have a formula idea that will bring us closer to your needs.

Please feel free to contact us if you need help.